Automatic Lubrication Systems

Optimize equipment performance by delivering precise lubrication automatically, reducing downtime and maintenance costs.

Automatic Delivery. Unmatched Reliability.

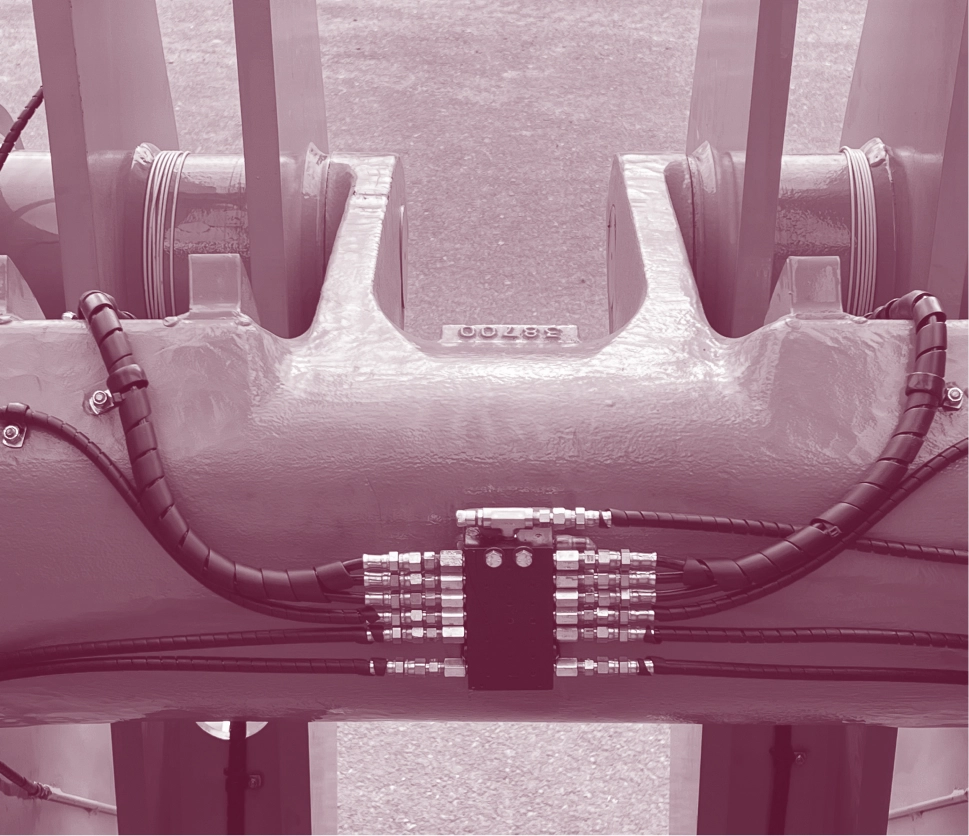

Guardian’s automated lubrication systems are purpose-built to deliver the right amount of grease or oil to the right point, at the right time—ensuring optimal protection for your equipment while eliminating the guesswork and inconsistency of manual maintenance. From single-point lubricators for isolated bearings, to fully integrated multi-line point grease and oil systems covering dozens—or even hundreds—of lube points, we engineer solutions tailored to your application.

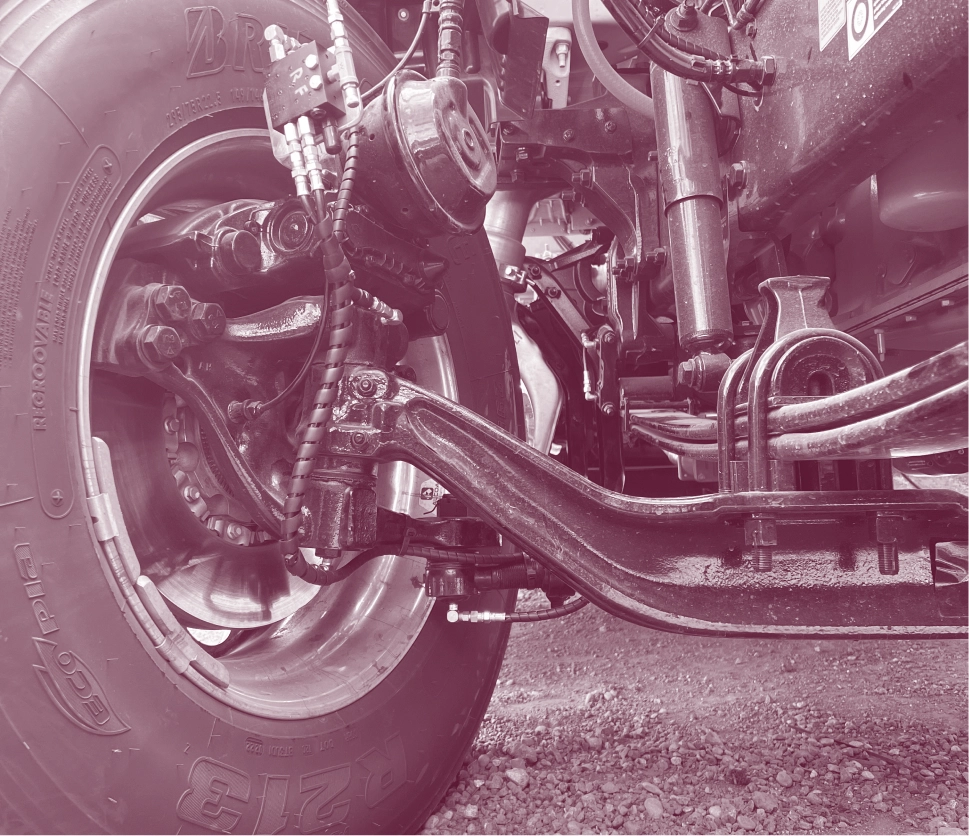

Our systems serve a wide range of industrial and mobile equipment, including sawmill machinery, conveyors, heavy trucks, mobile cranes, loaders, and processing equipment. Available in electric, pneumatic, hydraulic, or mechanical configurations, Guardian’s lubrication systems are fully scalable to suit your application. Even a few seconds of lubrication starvation can lead to rapid bearing failure, while over-greasing can cause seal damage and contamination ingress.

With Guardian, you eliminate both risks. Our systems deliver precise volumes based on equipment duty cycles—ensuring consistent protection that boosts uptime, extends component life, and significantly reduces grease consumption and labor costs.

Whether it’s a high-speed conveyor in a 24/7 facility or a loader operating in extreme field conditions, Guardian’s automated systems ensure every point gets what it needs—no more, no less. There’s no other company in the industry offering the same level of customization, system monitoring, and support that Guardian Reliability Services provides. From standalone electric pumps to fully integrated plant-wide lubrication automation, we help you reduce downtime, eliminate manual errors, and ensure equipment runs smoother, longer, and more efficiently.

Precision Grease & Oil Delivery Systems

Case study

Eliminating Grease-Related Failures with Automatic Lubrication

The challenge

A large equipment fleet was experiencing costly grease-related component failures and frequent downtime due to inconsistent manual lubrication. Each incident could exceed $10,000 in repairs, plus lost production time. Across over 300 machines, these issues significantly increased labor and maintenance costs.

The solution

Guardian Reliability Services (GRS) implemented multipoint autogrease systems fleetwide, delivering precise lubrication at the correct intervals without operator intervention. This eliminated missed grease points, reduced labor dependency, and ensured consistent lubrication in all operating conditions.

The results

With a 6-month ROI per system, the company now saves thousands of dollars annually per machine and has eliminated grease-related failures entirely. The automated systems reduced downtime and allowed operators to focus on production, driving higher operational efficiency across the fleet.

Ready to partner with us?

From system design to application-specific solutions, our experts are ready to support your operations with reliable, engineered services tailored to your facility.

Explore Our Capabilities

Call our experts at (360) 636-8369 for custom solutions