Mobile Auxiliary Filtration Systems

Keep your engine, hydraulic, transmission, and fuel system components operating at peak performance.

From Micron to Machine – We Keep it Clean

Microscopic Protection. Massive Results.

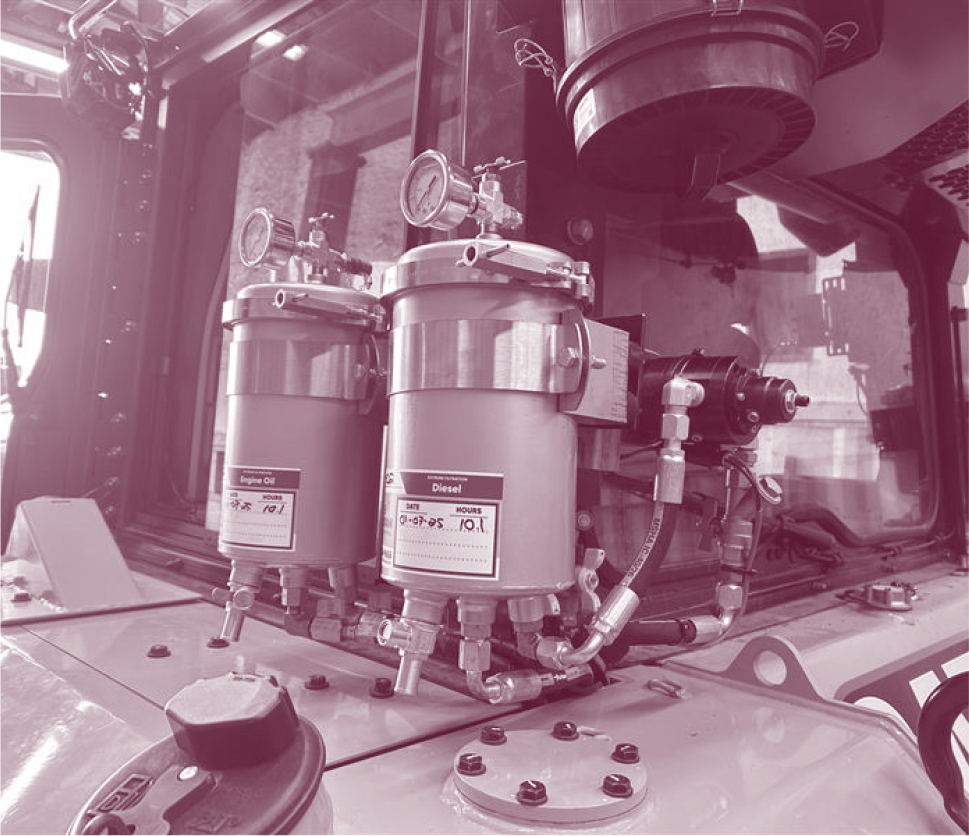

Custom-engineered kidney-loop filtration systems that extend oil life, boost performance, and keep your equipment running at its best. Our mobile auxiliary filtration units operate in a continuous kidney-loop configuration, ensuring maximum fluid cleanliness without interrupting production. Each system is custom designed for its specific application, ensuring seamless integration with your existing equipment and operational needs. Equipped with water-absorbing depth filter elements containing thousands of layers of tightly packed cellulose, these systems not only capture microscopic particles and free water before they can damage your equipment, but also feature an exceptionally high particulate-holding capacity—up to 8 lbs depending on the system—allowing for extended filter life and reduced changeouts.

A 1-micron particle is about 70 times smaller than the diameter of a human hair—yet these tiny contaminants cause the majority of wear in lubrication systems. By steadily processing small volumes of oil every second, our units deliver verified performance—removing 99.5% of particles—significantly increasing equipment performance, extending component life, and enabling longer oil drain intervals without compromising fluid quality. Best of all, these systems are designed to work in harmony with your existing equipment and will not void manufacturer warranties.

There is no other company in the industry offering the same level of seamless, fully customized filtration integrations that Guardian Reliability Services provides—ensuring your system operates cleaner, longer, and more efficiently than ever before.

The Guardian Systems

Ready to partner with us?

From system design to application-specific solutions, our experts are ready to support your operations with reliable, engineered services tailored to your facility.

Explore Our Capabilities

Call our experts at (360) 636-8369 for custom solutions